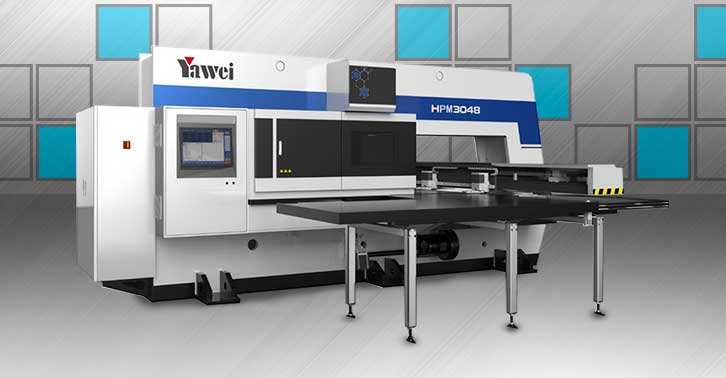

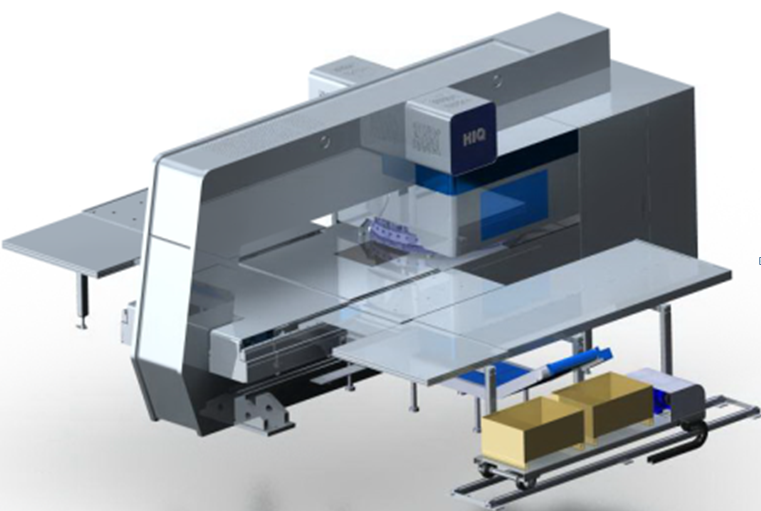

HPM Series.

High-efficiency electric servo punch head, can reach 2000 cpm. Automatic chip collection is supported. Independent drive for upper and lower turrets, easy to change toolings. Big storage of toolings: 64 stations. Extension with automatic system is supported.

Información:

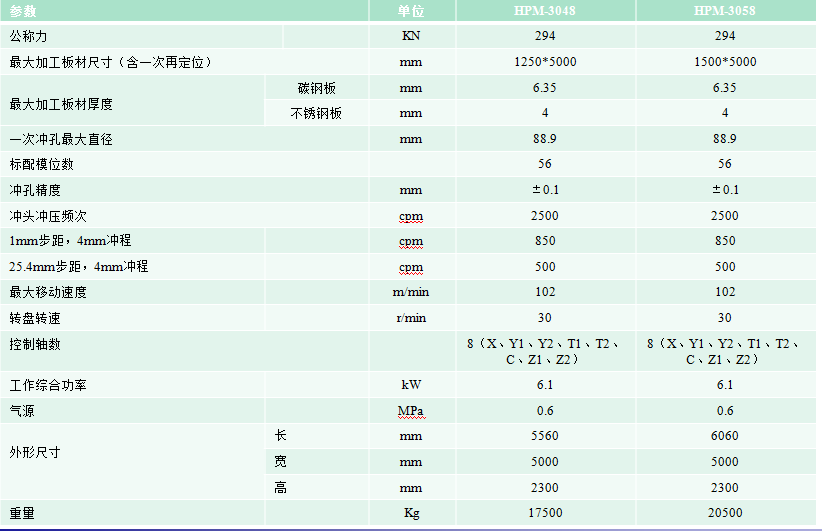

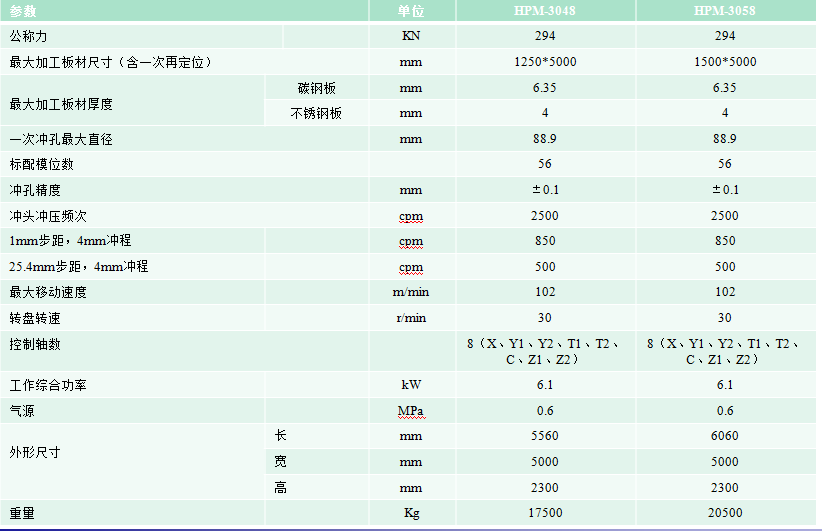

- Especificaciones

- Configuraciones

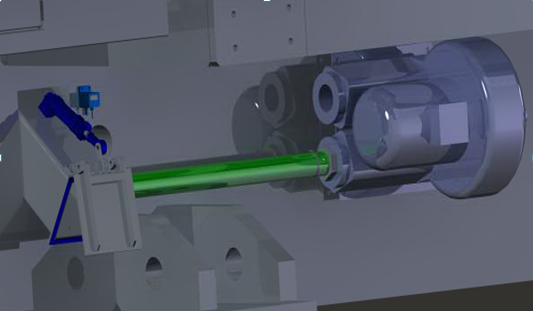

Adopt the double bar double stamping servo system

Serve to drive the crankshaft connecting rod mechanism, servo motor with hollow structure, reduce the transmission load inertia, benefit for efficient movement system, stamping speed faster, in addition the application of gap compensation device can effectively eliminate internal clearance, can provide a better life.

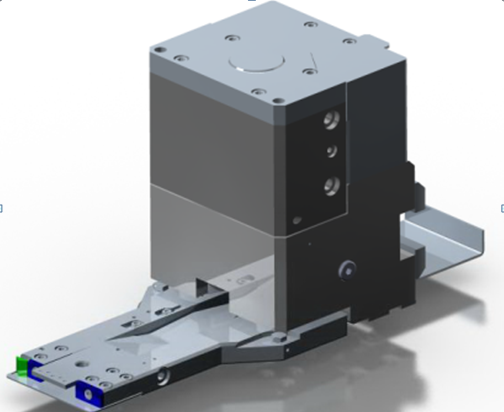

Programmable automatic floating clamp

Program automatic identification plate processing requirements, and according to the best place to adjust the clamp position, without having to manually in adjustment, the overall structure of floating sheet can adapt to real-time status in the stamping process automatically adjust height, avoid rigid bearing.

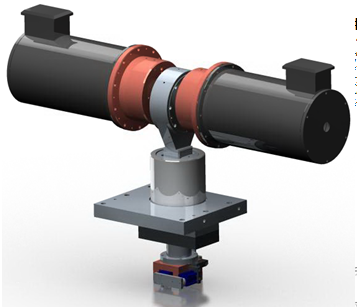

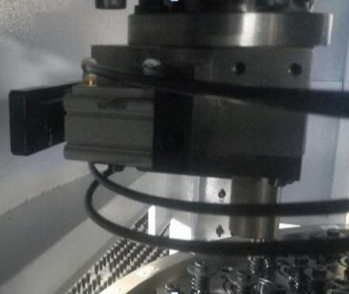

Rotary table structure

Turret USES high strength alloy steel casting, through a clamping precision processing and become, oxidation resistance and bearing capacity is strong, vibration absorbing and precision guidance performance is remarkable, stamping process is not easy to appear the phenomenon such as card mode, pick-up, and effectively solve the dense punching sheet deformation is too large when in use process problems.

With precision processing sound bushing, a sharp rise in the mold actual life.

Vacuum waste

Will fall in the punching machine tool bin closed, adopts the vacuum pump will be closed cavity after air time to form internal and external pressure difference, downward for punching waste, avoid waste recovery, the card.

Automatic down small material (optional)

System control cutting order, according to customer requirements die cutting small material (not greater than 450 mm * 400 mm), cancel the micro connection greatly reduce the workload of follow-up, the other interactive collection device for the conveyer end, expand the collection capacity.

On three head

Provide the Chinese and foreign three corresponding three times of turret location, reduce stamping partial load condition, improve the quality of workpiece processing.

Under the rapid loading and unloading

Unique U gap, without changing of the mold, and it is more convenient to use, humanized mould device of big station automatically, reduce the intensity of operator work fast loading and unloading.

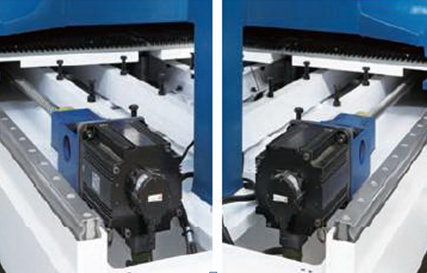

Y axis driving system

Y axis adopt gantry biaxial synchronous drive control, mature synchronous control technology with stronger power configuration make stronger dynamic response ability, adapt to tell run double ball screw axial bearing capacity better, ball screw adopts precision grinding structure, higher precision, longer service life.

Touch the man-machine interface

With 17 inch touch human-machine interface, in view of the punch design, simple operation, powerful functions.

Integrated graphics, offline simulation, dynamic simulation, mold contrast special functions such as punch.

Rotary die

Constant mesh transmission structure of patented technology, without having to worry about the secondary positioning error and wear and tear, repetitive positioning accuracy control within 0.03 mm, more to meet the needs of precision machining, precision turbine worm is used in the main drive system structure, and the T axis transmission linkage control, accurate read real-time position control system.