PBC Series.

Can choose servo motor as main drive to achieve better energy-saving performance. Mechanical crowning, better precision on thin sheets. High-speed backgauge system, high-speed hydraulic system, better efficiency. High-precision finger-stops, backgauge range can be extended, suitable for very wide sheets. Friendly HMI interface, 2D programming and 3D simulation display. Extension to bending automation is supported.

Información:

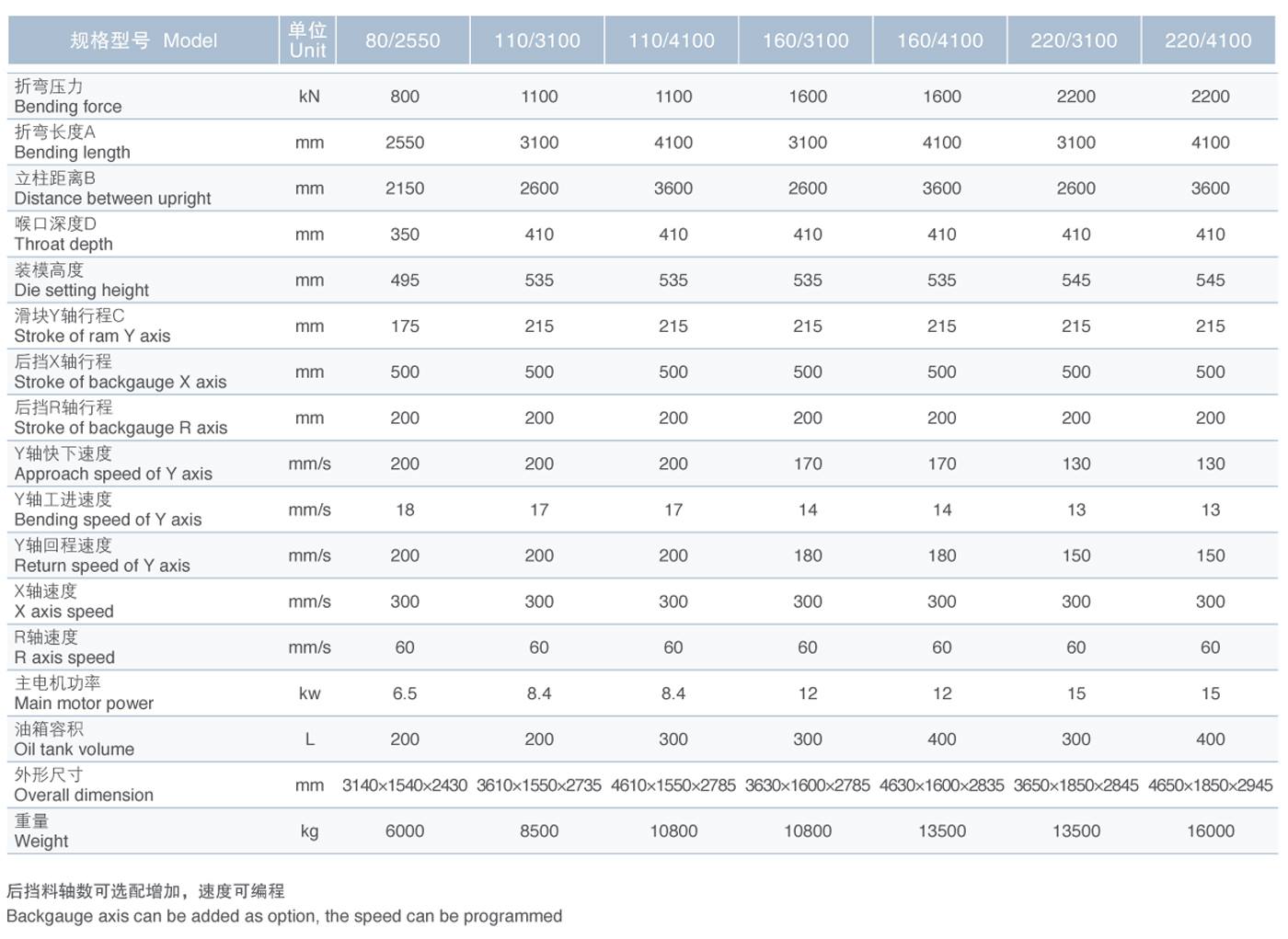

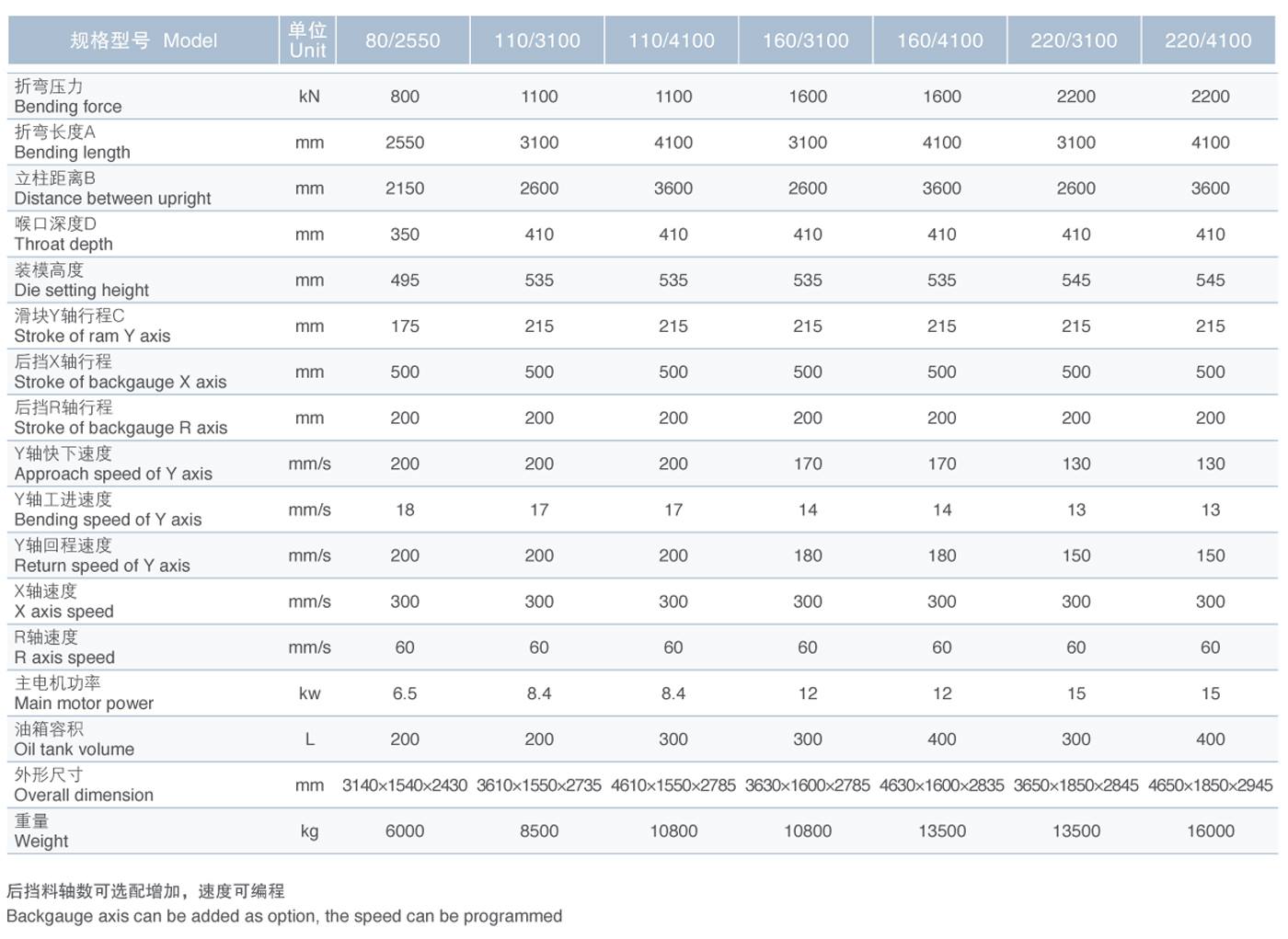

- Especificaciones

- Configuraciones

CNC system

10.4" TFT LCD screens.

800 x 600 lattice.

500 MHZ processor.

Storage capacity of 256 MB.

Mold base, 30 upper die, die under 60.

USB storage interface, network interface (optional).

Numerical control system.

Step by step from the former carrier adjustment

Standard configuration for step by step from the adjustment before the carrier.

Under the double V - type "T" quick change clamping way

Lower die adopts double V quick change clamping method, optional single V mechanical clamping or single V hydraulic clamping way, optional V lower die more wide workbench clamping way.

Quick grip on mould machinery

Mould clamping device on the standard configuration for mechanical quick grip.

Behind the double linear guide

Numerical control shaft adopts ac servo motor drive, precision ball screw, linear guide oriented.

Shaft: X r.

Speed: 300 mm/s 60 mm/s.

Stroke: 10-500 - mm to 200 mm.

Block: 3 only.